July 7 2025

When you own a boat there is always a time in the year when she needs to come out of the water.

La Bamba’s time was second half of June. While we were celebrating my Mum’s 90th (a bit early) in Wales with the entire Weightman clan, La Bamba was gently lifted up in a huge crane and put onto the hard.

I usually get very worried when boats are not safely in the water, so I’m glad I wasn’t there. David got some photos.

While out of the water, all sorts of useful jobs can get done, not least cleaning off the amazing green slime that covers everything in the marina.

Antifouling has changed fundamentally since we sailed the Contessa 30 years ago: back then I helped remove layers of lead-based antifouling and ended up having to stop as I was dizzy and seeing double – I guess my mask was not on properly. Nowadays that kind of anti-fouling is banned as it is toxic and destroys marine life.

Our antifouling now is basically a very slippery layer that makes removing the incredibly sticky and gloupy algae easier, and then it is reapplied. No sea life is harmed!

We also had a new hole put in the bottom of the boat – before you ask, it’s for the intake of our new water-maker. The water-maker is a very useful piece of kit if you’re planning to cross an ocean, as we are, as it converts sea water into drinking water.

Our water tank contains 270 litres, so with a crew of 4 for three weeks that would be just over 3 litres each per day: including all washing and cooking. Doable but not ideal, especially if you fancy a nice hot shower occasionally.

The water-maker is tucked in neatly behind the port side cushions.

We also had blades fitted around the propellor shaft to cut any ropes that might foul it. Lobster pots, loose fishing nets etc can cause problems and you really don’t want to be without a propellor.

The anodes were also renewed including those on the bow thrusters. These are sacrificial zinc lumps electrically connected to the engine and their job is to corrode first instead of the engine.

Then La Bamba was put safely back in the water.

The work on the boat has been a bit of an uphill struggle. As David says, it’s a bit like software engineering: where everything takes twice as long as you plan for. Also, if you don’t test it then it does not work – David has become extremely good at fixing things and, through necessity, now knows in detail how everything works.

We had hoped all the upgrades would be finished by mid May, giving us time to test all the systems and then set off early for the Canaries, but it is now July and the water-maker is only just installed and working. A few leaks were fixed and some pipe upgrades were done today giving us a fully working system which should produce 40 litres of fresh water per hour.

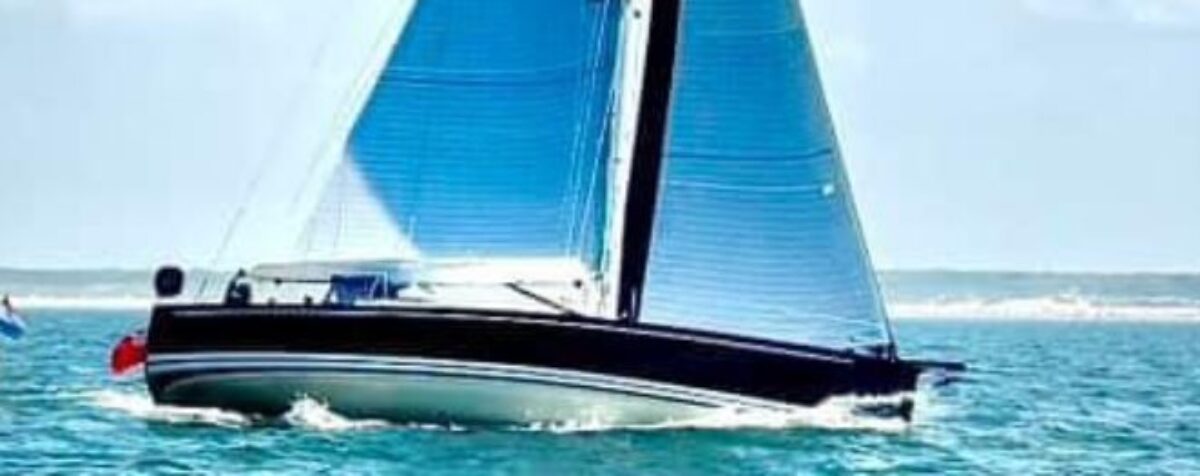

We are now ready to head off for a proper sail and actually leave the Solent – and we can try out our new sails and systems as we go.

Watch this space to see where we get to!